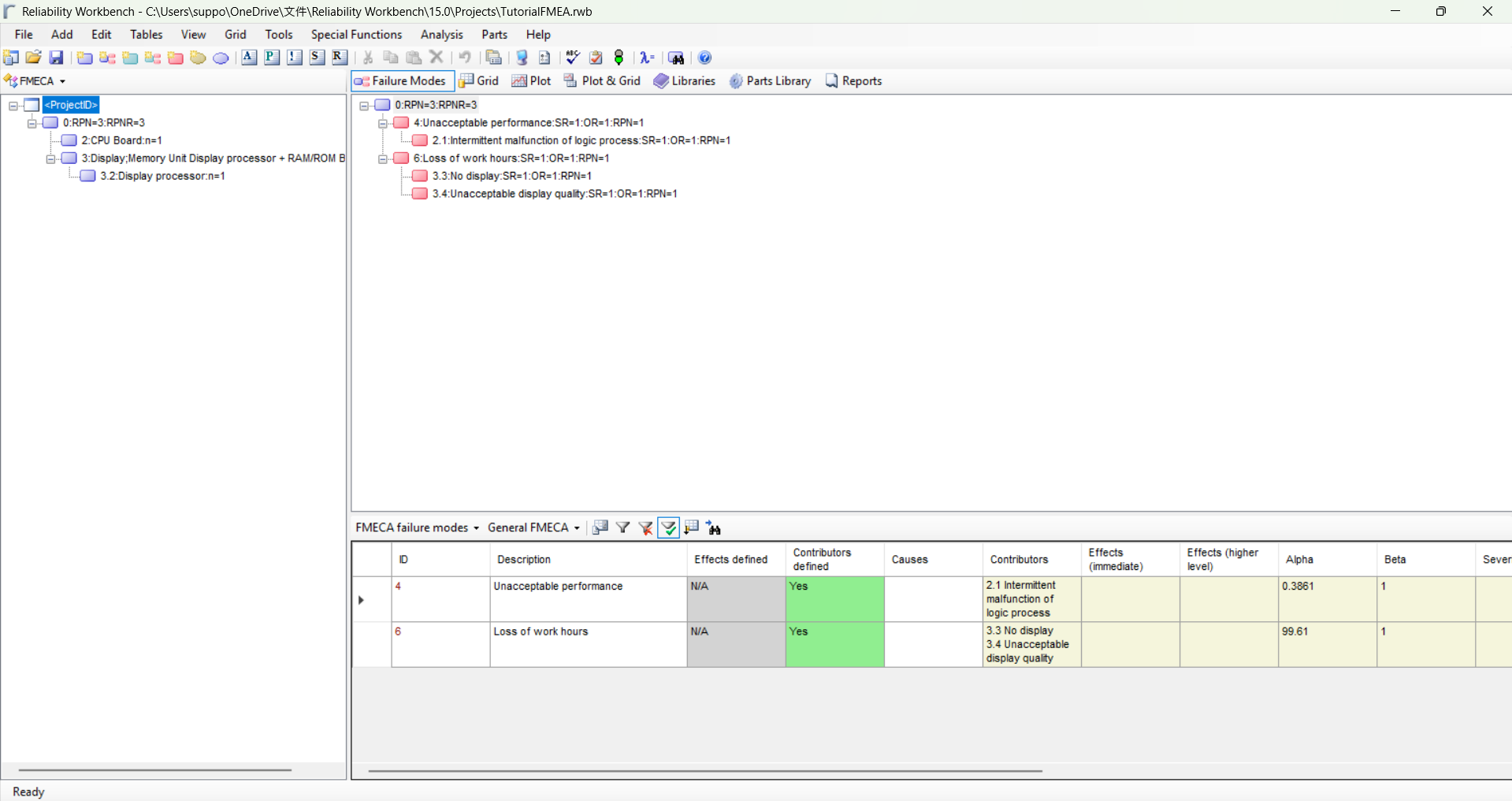

FMECA

Introduction:

- A Failure Mode, Effects and Criticality Analysis (FMECA) Module is a used for identifying potential failure modes in a system and classifying them according to their severity values.

- A FMECA is usually carried out progressively:

- Identifying failure modes and their effects (Failure Mode and Effects Analysis- FMEA).

- Identifying the Risk Priority number (RPN) which is based on the multiplication of occurrence of failures, severity of failure and detection of failure for FMEA.

- Hazard Assessment can be done through the FMECA module using FMEA or FMECA model.

- Failure Modes Effects and Diagnostic Analysis (FMEDA) can be done using FMECA module. ISO 26262 and IEC 61508 safety standards can also be implemented in it.

- Able to SIL calculation using IEC 61508 standard.

- Able to use the MIL-1629 standards for FMECA.

- Ranking failure modes using their effects according to the combination of severity and the probability of that failure mode occurring (Criticality Analysis - FMECA).

Key Features:

Our Reliability Workbench FMECA and Fault Tree+ modules have been tested and certified by SGS-TÜV as suitable for safety analyses according to ISO26262.

Some of the FMEA Software features are summarized below:

- Creation of Apportionment library and Phrase library for fast data entry

- Effects of the failure modes can be automatically traced through to system level

- Automatically severities can be assigned and there will be automatic criticality calculations

- Multiple failure effects permitted for a single failure mode

- Failure detection filter facility and User-definable severity category libraries

- Spelling checker and global text replacement for the easy convenience

- Sub-projects may be linked to a master project

- Automatic data transfer from prediction modules

- Drag and drop components to the RBD module

- Automatic fault tree construction facility

Benefits:

- The FMECA module allows the customers to construct the FMEA and FMECA in the required standards.

- The FMECA Module is its ability to automatically trace failure effects, severity values and failure causes through the system hierarchy.

- Failure rate and criticality values are automatically calculated by the program.

- Able to plot the criticality matrix (severity classification vs criticality), contribution plot (Failure mode vs Failure rate) and RPN plot.

- The FMECA Software Module will also filter detectable and non-detectable failures in reports

- Able to determine the ratio between the frequency of detectable failures and total failures.

- Apportionment libraries and Phrase libraries make an added advantage to FMECA building in the software.

- Automatic conversion from FMECA module to RBD, Fault Tree, Allocation.

- Import and Export can be done easily.